Millie & Noah partners with every client to design their one-of-a-kind, whether they are unsure of what they want or have a clear vision in mind. The collaboration runs throughout the design process, allowing us to understand the person and perfect the design along the way. Whatever our customers' needs, we leave no stone unturned to create apiece for them to love for years to come.

01 |

As we start brainstorming, we will provide you with sketches of a range of potential designs to get a better sense of which direction to go in. From there, we will guide you through several sketch iterations before finalizing the design. Before starting production, we will provide you with formal renderings to help you visualize the piece and make any adjustments if needed. in many cases, a physical prototype can be shipped to you to try on.

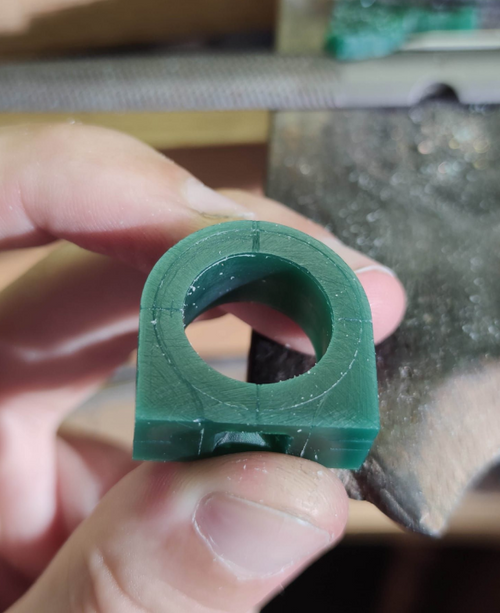

02 | THE WAX MODEL

Once the design is approved by you, a 3D model will be made by hand or computer-assisted design (CAD).

02 | THE WAX MODEL

Once the design is approved by you, a 3D model will be made by hand or computer-assisted design (CAD).

03 | THE CASTING

Next, the wax model is used to make the gold cast which is then readied for stone setting.

03 | THE CASTING

Next, the wax model is used to make the gold cast which is then readied for stone setting.

Gems are then set into the gold frame according to the design.

Once the stones are all set, the piece is polished one last time before it is ready to be shipped.